Food Preservation

Modified Atmosphere Packaging (MAP)

Gas Mixer

MANÁFOOD® CLÁSSICO

Dynamic gas mixer for mixing two to four gases, with adjustment of the gas concentration from 0 to 100%, control of the flow rate and outlet pressure of the gas mixture. Also includes safety valves and sintered filters for the mixer inlet doors. Flow rate up to 3.6 m3/h.

Due to the high monthly consumption and its cost, food grade premixed gas mixture packaged in high-pressure cylinders can greatly affect the final cost of the food product. With the gas mixer MANÁFOOD®, meat processing companies (beef, pork, poultry, …), bread, pasta, cookies manufacturers, coffee powder producers, … all are able to blend, on site, their own gas mixtures from pure gases and most of the time, the ROI is under 12 months.

Suitable for food preservation/conservation of MAP – modified atmosphere packaging, aiming to increase shelf life, preserving flavor, shape, color and freshness and maintaining the quality of the food.

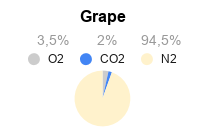

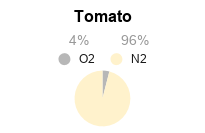

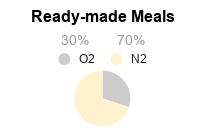

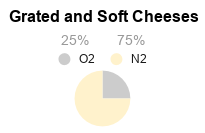

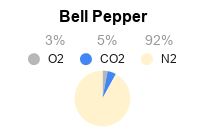

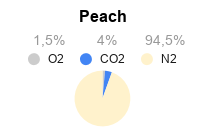

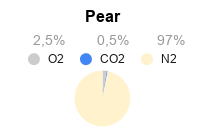

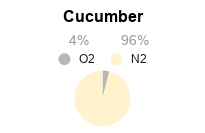

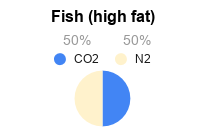

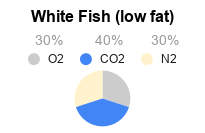

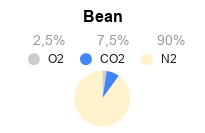

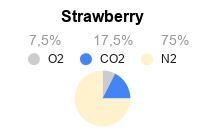

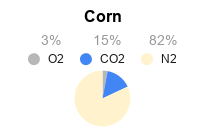

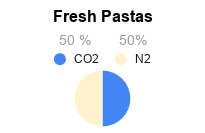

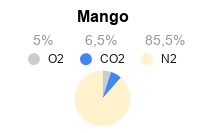

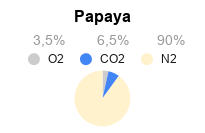

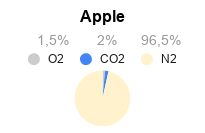

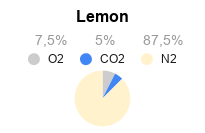

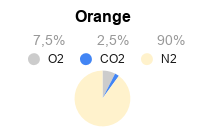

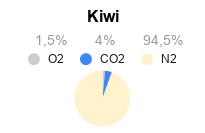

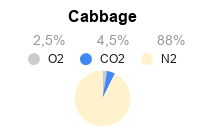

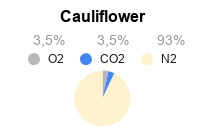

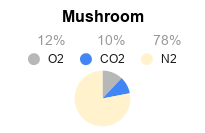

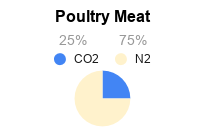

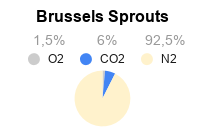

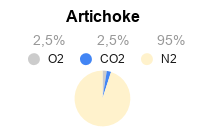

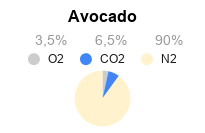

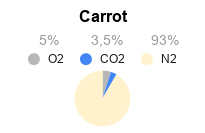

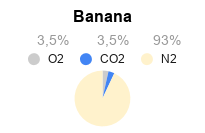

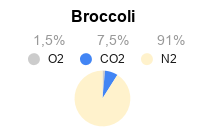

Inside the food packaging, the atmosphere that protects, preserves and prolongs the food´s life is achieved by combining CO2, (Carbon Dioxide), N2 (Nitrogen), O2 (Oxygen) and some cases CO (Carbon Monoxide).

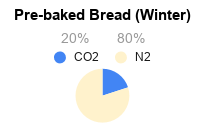

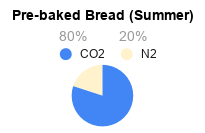

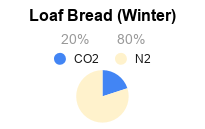

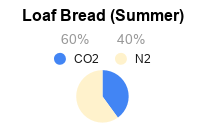

Depending on the food to be packaged, the gas mixture changes as well as each gas content. Others gases can also be included to the food grade gas mixture.

The gas mixer MANÁFOOD® can generate mixtures of gases for modified atmospheres packaging or storage of the most diverse food products, including beef, pork, fish, bread, fresh pasta, fruit, vegetables, eggs, sausages (salami, ham, … ), frozen meals, cheese, milk, etc.

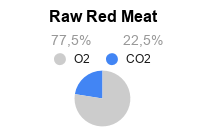

The shelf life of raw red meat can be increased to up to two months, with a high concentration of oxygen (O2) (70 to 85%) and stored at -1 ° C. The high concentration of oxygen (O2) ensures the maintenance of the red color, for example, for minced meat, the shelf life has increased from 7 to 10 days.

Currently, the use of gas mixtures is very common in the food processing and packaging segments, and the vast majority of producers already know exactly which gas mixtures is best suited to their food product.

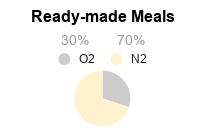

An example of a widely used gas mixture is that of 30% carbon dioxide (CO2) with 70% nitrogen (N2). This gas mixture of CO2 and N2 is used in many food products, especially in the retail packaging stage.

Gases perform different functions too, and sometimes for different products. Normally, nitrogen is used to exclude oxygen, reduce oxidation and inhibit fungal growth. However, for some products like cheese, for example, it is useful to keep it fresh.

Different gas mixtures are used at different stages of the process, and there are still suitable mixtures according to the type and size of the packaging (for example: retail packaging x wholesale packaging).

Another very common gas mixture is mixing with a high concentration of oxygen (O2), combining with CO2, perhaps 80% O2 and 20% CO2 (most commonly used for red meat). High concentrations of oxygen in this case help to keep the meat fresh and look good for longer.

In all applications of gas mixtures in the food segment, the MANÁFOOD® gas mixer is the most economical equipment, which will generate the correct mixture that food or packaging needs.