Nitrogen for Beer

Dispense your beer perfectly and consistently

Gas blender for beer dispensing

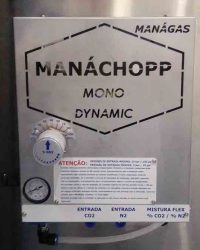

MANÁCHOPP® MONO DYNAMIC

MANÁCHOPP® MONO DYNAMIC is a gas blender for draft beer dispensing, which combines CO2 (Carbon Dioxide) e N2 (Nitrogen) with great gas mixture accuracy (+/- 1%). It generates one constant and pre adjusted gas mixture.

Main benefits are:

– Highest quality from every pint of beer pulled out of the keg;

– Provide the right ratio of gas mixture (CO2/N2) to push draft beer and at the same time, protect the beer integrity from the keg to the glass;

– Avoid beer waste and increase profit – the right gas mixture can push up to 95% of a beer keg volume;

SINGLE GAS MIXTURE – DYNAMIC

Each draft beer style needs a specific gas blend to maintain its original characteristics, flavor and taste.

THE DYNAMIC/FLEXIBLE MIXTURE FROM 0 TO 100% THAT YOUR BEER NEEDS (CO2 + N2)

O MANÁCHOPP® MONO DYNAMIC is a gas blender for draft beer dispensing, which combines CO2 (Carbon Dioxide) e N2 (Nitrogen) with great gas mixture accuracy (+/- 1%). It generates one constant and pre adjusted gas mixture.

THE DYNAMIC MIXTURE FROM 0 TO 100% THAT YOUR BEER NEEDS (CO2 + N2)

The flexibility of adjusting the gas mixture in real time represents the ideal solution to increase the yield of the beer keg, as it allows it to remain connected to the tap without the formation of much foam.

Features:

- Easy installation and use;

- Able to push 15 kegs at the same time (depends on the different beer styles and inlet pressure);

- Great gas mixture accuracy;

- Customized gas mixture – each gas mixture can be developed to address a specific customer or beer style demand.

MANÁCHOPP® gas blender consists of a small metal cabinet, which can be fixed close to the kegs of beer. Very easy to install, safe, does not require electrical power to work, no need for maintenance or any adjustment to start working.

Important Note:

MANÁCHOPP® gas blender must not be connected directly to the gas cylinder without it having a first stage pressure regulator installed. Before using the product it is very important to consult the installation manual, and make sure that the first stage regulator is regulated according to the pressure limits below:

MAXIMUM Inlet Pressure: 10 bar/150 psi

MINIMUM Inlet pressure: 5 bar/70 psi